Equipment Compositions and Functions

Bottle block cylinder & Infeed Screw

Bottle block cylinder is used to prevent the bottle go into the filling equipment during normal running and default .It can be operated manually and automatically. If there is not enough bottle supply, the bottle block cylinder controls the starwheel and reduces the running speed as well.

Bottle infeed screw drive is composed by the 2 level reducer, the 1st level is the cone gear drive, for driving the bottle in screw and bottle in chain, the 2nd level is bottle in screw drive box, for adjusting the bottle infeed screw and position adjustment during bottle shape changing .

Rinser

Composed by Dispenser, rinsing clamp, rinsing water recycle, there is a fixed rinsing time, the empty bottle was held by a fixed track, rinsing, drying, then reaches the cleaning purpose.

Filler (Controlled by Flowmeter)

Rotary wheel fully made of stainless steel SUS 304.

Non contact gravity filling method.

Valves are controlled by flowmeter

Product cylinder and filling valves are made of SUS 304

Filling valves are reasonably structured with accurate filling.

Filler is driven through gears inside the machine frame.

ROPP aluminum cap capping machine part

Screw capper is our company introduction of French technology, self-designed and manufactured, with peer leadership, stable performance equipment.

Screw cap heads have novel structure, beautiful shape, easy to clean, easy to adjust. Screw cap pressure is adjustable, so that after sealing cap thread clear, full, the appropriate pressure on the top of the bottle to ensure reliable sealing.

304 stainless steel cap machine, reducing the secondary pollution of bottle cap, 304 stainless steel under cap tank, cap storehouse and under cap tank with electric no cap check system, Automatic control conveyor cap machine and whole machine speed, can be realized without bottle don’t conveyor cap, off cap and without cap can auto-shut-down.

Rotary cap unscrambler adopts air blow cap unscrambler, without damaging the surface of cap, avoiding the cap extrusion deformation, hopper have check cap switch, control.

Discharge Starwheel

Discharge Conveyor

Driving motor is frequency inverted to synchronize with the filling line to prevent bottles from falling.

Discharge conveyor is equipped with photocell switch to slow down and stop filling line in case of fallen bottles.

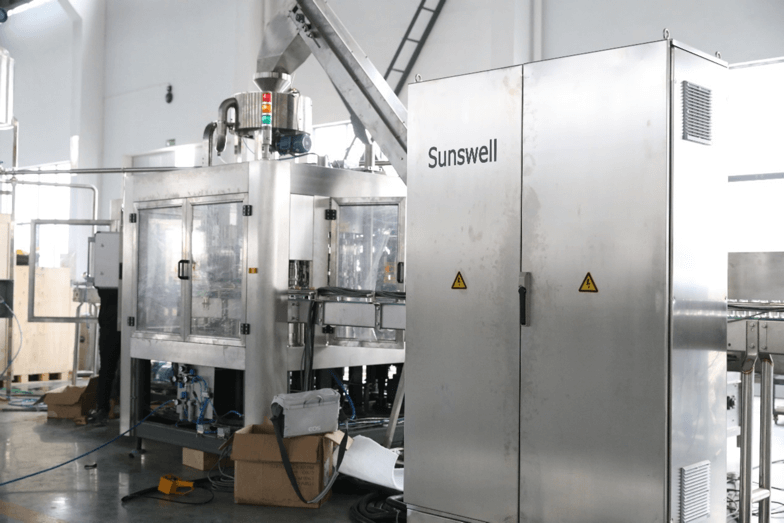

Machine Frame

The machine frame is a welded structure of high quality carbon steel with the surface anti-rust treated and coated. The machine frame is wrapped with stainless steel sheet.

Driving system of the 3-in-1 Unit is positioned under the machine table. One main motor provides driving power via gear transmission.

The gear transmission system is an interleaved arrangement of steel gears and nylon gears.

The output shaft of the main motor is equipped overload protection to secure machine safety.

Electrical control system

The electrical cabinet is made of plated carbon steel. From bottle infeed to bottle discharge, a PLC controls the fully automatic operation of the 3-in-1 Unit.

Main Configuration

Product storage tank and filling valve: Stainless steel 304

Material of rotary tray and machine platform of rinser and filler: Stainless steel 304

Touch screen: Pro-face

PLC program controller: Mitsubishi

Inverter: Mitsubishi

Photoelectrical controller: Leuze

Proximity switch: Leuze

Other electrical components: Siemens, Schneider

Pneumatic component: Airtac

Main motor: ABB