| No. | Item | Configuration description |

| |

| 1. | Screw material | ultra-high molecular polyethylene |

| 2. | Screw dive | gear drive with safety clutch Brand:Nangjing gongnuo |

| |

| 1. | Bottle contact star wheel guide plate | ultra-high molecular polyethylene,height;About20mm |

| 2. | Bottleboard | material 304, thickness≥6mm |

| |

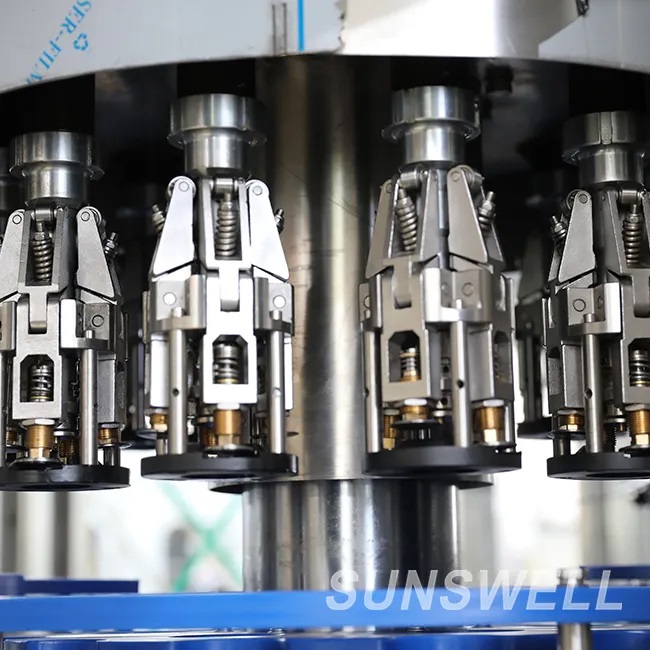

| 1. | Rinse clamp | (1)The material is 304, and the bottle clamp is ultra-high

molecular polyethylene

(3)Plastic bearing brand: IGUS

(4)Active bottle clamping, cam opening |

| 2. | Rinsing medium | (1) Gas flush bottle

(2) pneumatic dynamic and static seal

(3) With gas filter, filter element brand:PALL

Valve:Liyang Sifang or equivalent brand |

| 3. | Other | (1) Rinse clamp mounting tray material:304

(2) With gas collection fan |

| |

| 1. | Liquid tank | (1) Material304,bottom plate≥16mm

(2) With liquid level detection element, automatic control of material feeding |

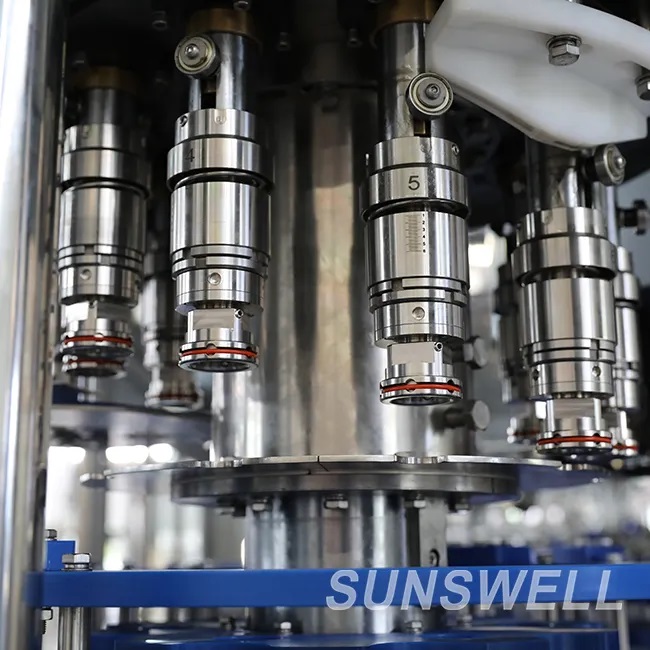

| 2. | Filling valve | (1) Valve opening executive motor:IGUS

(2) Non-contact filling valve with tailing suction back

(3) Material contact liquid material:304

(4)Valve:Liyang Sifang or equivalent brand |

| 3. | Rotary pneumatic solenoid valve | Brand:FESTO or SMC |

Aluminum cap screwing machine |

| 1. | Screw cap head | (1) Capping head is aluminum, made in China

(2) With thread knife and back sealing knife,Spring tension is adjustable

(3)It cannot be sealed without a lid |

| 2. | Cap scraper | (1) Installed above the filling capping wheel

(2) Spring force hook cap with spring retaining section |

| 3. | Integral component | (1) Screw cap with bottle bottom plate

(2) Including inner guide rail |

Plastic press capping machine |

| 1. | Press cap head | (1) Screw cap head is visible on the outside and made of

material 304

(2)With adjustable spring pressure and scale |

| 2. | Shift cap tray | (1) Installed on the side of the capping machine

(2) The cap is sent from the cap tray that will be placed when

there is a bottle |

| 3. | Integral component | (1) Screw cap with bottle bottom plate

(2)Including inner guide rail |

| |

| 1. | Aluminum cap supply system | (1) Waterfall lid lifter

(2) Power for domestic motor,with UL certification

(3) With reverse cap rejection,and low pressure ultraviolet

sterilizer |

| 2. | Plastic cap supply system | (1) Cap through the belt

(2) Power for domestic motor,with UL certification

(3) With cap sorting device, reverse cap rejection,and low

pressure ultraviolet sterilizer |

| |

| 1. | Main rack | (1) Stainless steel 304 welded construction

(2) Bottom plate22mm,covered with stainless steel 304 plate

(3) Adjustable foundation bolt and base anchor,material:304 |

| 2. | Window sealing | (1) Closed,flushing area has a fan for air extraction,filling and

Sealing area with positive pressure FFU. Brand:AAF |

Other major configuration

|

| 1. | Main electric control cabinet | Material:304,drawing block |

| 2. | Electric appliance configuration | (1) PLC:Siemens or equivalent brand

(2) Converter:Danfoss

(3) Sensor:SICK

(4) Touch screen:Siemens or equivalent brand

(5) Operation stand:Aluminium alloy,rotary lifting

(6) Low-voltage electric:Schneider |

| 3. | Other | (1) Plastic bearing brand;IGUS

(2) The prime power motor is SEW

(3) Wire color refer to NEC standard requirement or required by

party A

(4) Centralization lubrication:SKF |