The machine is used for 3L-10L water filling, which is composed of washer, filling and capper.

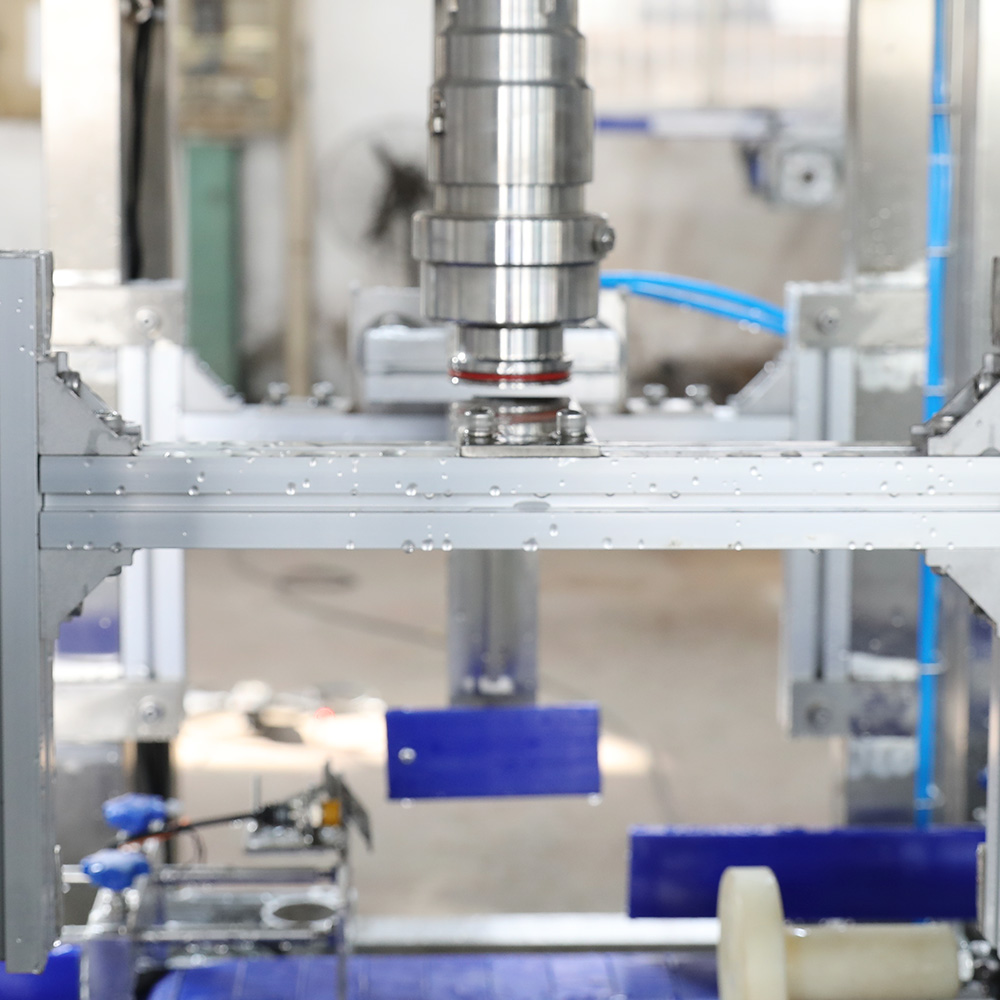

1.304 stainless steel insert type filling nozzle, two time high precision filling, filling volume adjustable.

2. Water pump: 304 stainless steel pump. three washing pumps and one filling pumps.

3. Mitsubishi PLC controlling system, all full-automatic working, Schneider & Omron brand other electric parts

4. With AIRTAC brand air cylinder, F.R.L. Combination and Electromagnetism valve for air cylinder.

5. Machine frame and body: all 304 Stainless Steel, combine with clear fiber glass windows Automatic 5 gallon bottle washing machine

3L, 4L, 5L big bottle linear 3-in-1 Water Filling Machine Main features

Rinsing part

The Rinsing machine connect with empty bottle conveyor frame, when empty bottle input rinsing machine extent, through

photoelectrical reaction, Circuit control system command Pneumatic electromagnetic valve movements, let the Clip bottles of

cylinder clip the bottle, then the oVERTUrn cylinder operate, the bottleneck turn down, then the pure water pump open, spurt pure

water to the bottle, after 30s, stop it, the oVERTUrn cylinders reset, input the conveyor system and go to filling machine.

Filling machine

After-wash empty bottle input the filling machine through conveyor system, two push-barrel cylinders operate beside conveyor, then

the bottle arrive filling part, the bottle bottom separate the conveyor belt. After filling, the bottle drop on the conveyor belt.

Output to the capping part.

Screw capping machine

The screw capping machine is made of 4 screw capping heads frame, after the filled bottle convey to the screw capping machine

station, through air cylinder start to screw cap, again and again, the finished bottle output to the warehouse and check.

Equipment structure:1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing pump. 2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder. 3. Capping system: Combined with capper, cap sorter and cap falling track. 4. Driving system: Combined with main motor and gears. 5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates. 6. Electrical controlling system: this part is frequency inverted, PLC controlled and touch screen operated.