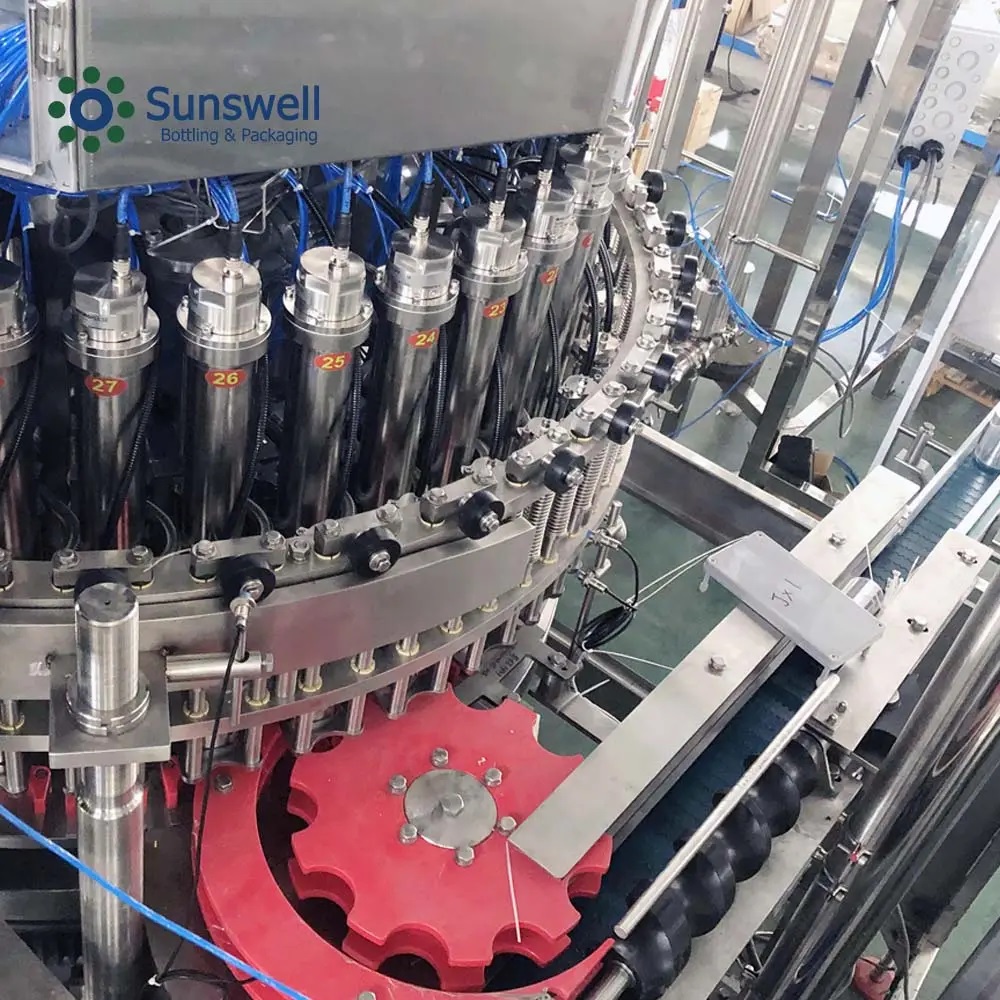

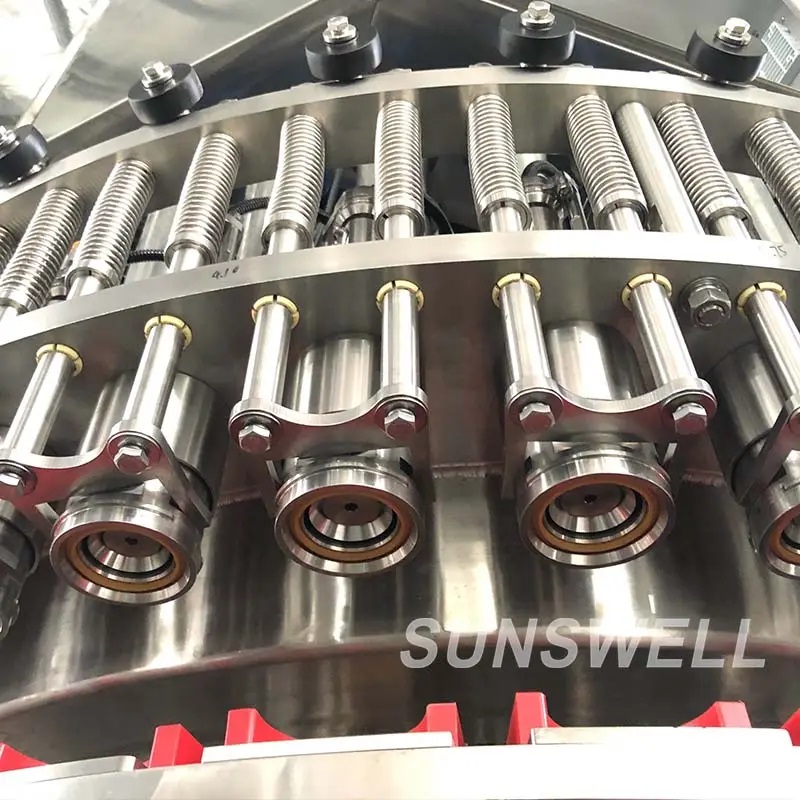

Set up in 2008, Sunswell leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

We can customize liquid food production lines according to customers' demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: ensure you to reach business goals with most optimized planning.

Why choose us?

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)10+ years of global market experience

(4)Serve customers over 50 countries and regions worldwide

Office & Factory & Workshop