Product Description

Palletizer mainly is used to Palletize various of glass jar, PET jar. It will palletizer the empty bottle from conveyor to stack

again and again. Save much manpower, improve working efficiency.

This Depalletizer Machine could divide into Semi-Auto and Full-Auto type, also could divide into Low Level Depalletizing Position type and High Level Depalletizing Type.

Machinery Structure

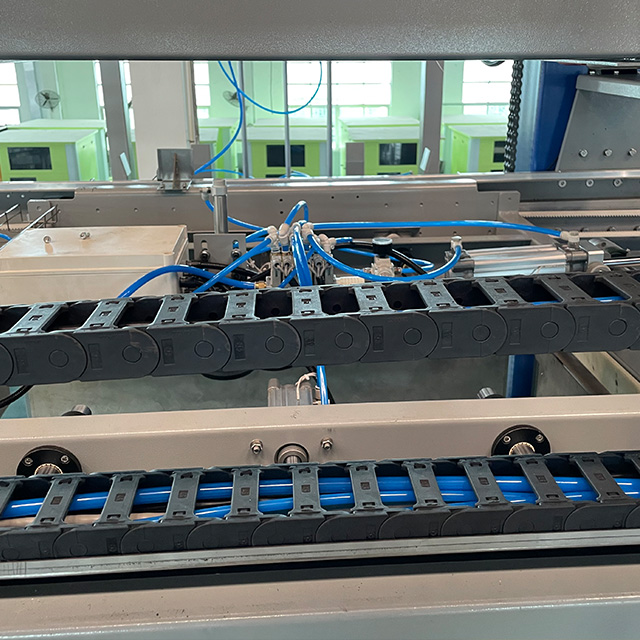

Full pallet conveyor, pallet life device, whole layer cans pushing trolly, isolate remover, empty pallet stacker.

Pallet stacker

Isolate pad pneumatic mover

Four sides cylinder clamp holder

Advantages

1. High performing

2. Reliable

3. Flexible (in terms of container, format and pallet)

4. Quick and easy format changeover

5. Completely automated

6. Fully customizable

7. High operator safety standards

Appliance scope

For various metal cans, glass bottles, plastic bottles for layered depalletizing.

Depalletizer workflow and principles

1. Forklift put the whole stack cans/bottles into unstacking station (hydraulic lift table)

2. Chain lifter will transit the packed pallet to the upper most of the depalletizer.

3. Four sides clamps will hold the uppermost whole layer cans or bottles from four sides, moving in parallel to the outlet multi lane conveyor.

4. The the four sides cylinder clamps will back to original position.

5. Pneumatic absorb hands will absorb the next layer top side isolate pad, move the pad to pad collector.

6. Chain lifter, hold the board rise to a certain height crib.

7. Do the same procedure until the last layer, hydraulic lifts pallet fell to bottom, then transit to empty pallets stacker.

8. Forklift remove the empty pallet.

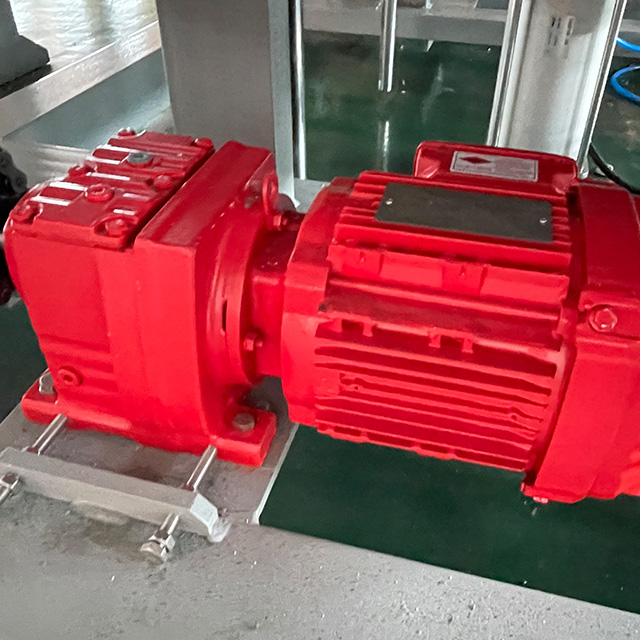

| Item | Brand |

| PLC | Siemens/Mitsubishi/Schneider/Delta |

| Motor | SEW/ABB/Siemens/Tongyu/Nord/Weg/Jie |

| Pneumatic control | Airtac/Festo/SMC |

| Low volts component | Schneider/Siemens/Chintai/Delixi |

Technical parameters

Model: XD600

Capacity: 36000CPH (330ml)

Feed adjustable: +/-50mm

Platform: carbon steel

Conveyor height: 3100mm

Pallet height: 2800mm

Workshop height: 4500mm

Empty pallet stacker: ten pallets

Pallet size: L1420mm*W1120mm*H150mm (customized)

Overall dimension: L5800mm*W1350mm*H3700mm

Weight: 3700kg

Power

Power supply: 380V, 50Hz, 3PH

Total power: 2.05KW

Main motor: 0.75KW

Can conveyor motor 1: 0.75KW

Can conveyor motor 2: 0.75KW

Our company leads the market in the field of machinery with advanced technologies in terms of our beverage packaging.

We provide a wide range of beverage packaging products. Our machinery has the most comprehensive scope. We enjoy worldwide praise with 10 years of global marketing experience. We have a large number of customers worldwide and we have various end products.

Our product range covers all types of machinery for the packaging of liquid, including water, tea, juice, carbonated soft drink, energy drink, alcoholic drink, beer, edible oil, dairy products, etc.

We provide good quality and technology from raw material to bottled liquid. We are a good supplier, well known for developing innovative high-end products and new technologies.

Our company offers a complete portfolio of support and consulting services, from project engineering to customized solutions and after-sales services. We also provide production optimization, training and advisory services, even end product development. We are looking forward to establishing relationships with you in the near future.

FAQ

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If

needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.